Are you in search of the best gate valves with pneumatic actuators for your next project? Look no further! Gate valves are an essential component of any piping system, and selecting the right one can make all the difference. With so many options available on the market today, it’s easy to feel overwhelmed. However, we’re here to help simplify things for you. In this blog post, we’ll explore some of the top gate valves with pneumatic actuators that will meet your needs and exceed your expectations. So sit back, relax, and let’s dive into everything you need to know about these fantastic gate valves!

Intro

The introduction is like the gateway to your blog post, it’s what hooks readers in and gets them interested. In this case, we’re discussing gate valves with pneumatic actuators. These types of valves are essential for a wide range of piping systems, from industrial applications to commercial use.

Gate valves come in many different varieties, including those with electric or manual actuators. However, when it comes to efficiency and ease of operation, pneumatic actuator gate valves are hard to beat.

Choosing the right gate valve can be challenging since there are so many options available on the market today. That’s why we’ve curated a list of some of the best gate valves that feature pneumatic actuators – making it easier for you to decide which one will work best for your project needs.

In this article, we’ll explore each type of actuator and examine its benefits and drawbacks so you can make an informed decision about which option is perfect for your specific application requirements.

So without further ado let’s jump into exploring some fantastic gate valve options that feature pneumatic actuators!

Pneumatic actuator gate valve

Pneumatic actuator gate valves are a popular choice for many industries due to their efficiency and reliability. These types of valves use compressed air to power the valve’s opening and closing mechanism, providing quick and precise control over the flow of fluid or gas through the pipeline.

One advantage of pneumatic actuator gate valves is their ability to operate in harsh conditions, such as high temperatures or corrosive environments. This makes them an ideal choice for applications in chemical processing plants, refineries, and offshore oil rigs.

Another benefit is their ease of maintenance since they do not require electricity to function. Pneumatic actuators can also be easily replaced if necessary, reducing downtime during repairs or upgrades.

It’s worth noting that while pneumatic actuator gate valves offer fast operation times, they may not be suitable for all applications due to limitations on pressure ratings and temperature ranges. Therefore it’s important to consider your project requirements carefully when choosing a valve type.

Electric actuator gate valves

Electric actuator gate valves are another type of gate valves that offer numerous benefits. They use electric power to control the valve, making them ideal for remote operation and automation. Electric actuators provide precise control over fluid flow through the valve with minimal effort.

One of the best electric actuator gate valves in the market is the AVK RW Gate Valve with Electric Actuator. This valve features a robust design that ensures durability and reliability even in harsh environments. It has an epoxy-coated ductile iron body that protects against corrosion and wear.

Another notable electric actuator gate valve is the DeZURIK AWWA Butterfly Valve with PEC Eccentric Plug Valve Actuators. This valve features a high-performance eccentric plug design that provides excellent shutoff capabilities and low-pressure drop performance.

Selecting a suitable pneumatic or electric actuated gate valve depends on various factors such as application requirements, environmental conditions, and size limitations, among others. The five mentioned above are just some of our top picks based on customer feedback and industry standards.

Electric actuator gate valves are another type of valve that operates using an electric motor to open and close the valve. These types of gate valves offer greater control and precision compared to pneumatic actuators because they can be programmed with specific opening and closing speeds.

One of the best electric actuator gate valves on the market is the Bray Controls Series 70 Electric Actuated Gate Valve. This valve offers reliable performance, easy maintenance, and long-lasting durability making it ideal for a range of industrial applications.

Another great option is the Flow-Tek F15/F30 Flanged Series Electric Actuated Gate Valve which features a compact design, corrosion-resistant construction, and exceptional sealing capability.

Whether you choose a pneumatic or electric actuator gate valve will depend on your specific application needs. By considering factors such as pressure requirements, usage frequency, and system compatibility you can make an informed decision about which type of valve is right for your operation.

Gate valves with pneumatic actuators are a reliable and efficient choice for many industrial applications. They offer precise control and automation of fluid flow, making them ideal for use in pipelines, refineries, power plants, and other facilities.

However, if pneumatic actuation is not suitable for your application or you simply prefer electric actuation over pneumatics, there are also electric actuator gate valves available on the market. These operate using an electric motor instead of compressed air to open and close the valve.

Electric actuator gate valves come in varying sizes and materials to suit different applications. They can be controlled remotely through a computerized system or manually by operating switches or buttons located on the valve itself.

Whether you choose a pneumatic or electric gate valve ultimately depends on your specific needs and preferences. Whichever type of valve you choose will provide reliable performance and help ensure smooth operations within your facility.

Manual actuator gate valves

Manual actuator gate valves are an essential component of any piping system. These types of valves require manual effort to operate, as the name suggests, and do not have a motor or pneumatic power source. Unlike electric or pneumatic actuator gate valves, these valves offer simplicity in operation and maintenance.

One advantage of a manual gate valve is that it does not rely on external power sources such as electricity or compressed air. This makes them ideal for remote locations where power supply may be limited or non-existent.

However, one major downside to using a manual gate valve is its slower response time compared to electric and pneumatic actuators. It requires human intervention which can lead to delays in operations especially during emergency situations.

In addition, manually operated gate valves require regular checks and lubrication to ensure smooth functioning which can increase maintenance costs over time.

What is a Gate Valve?

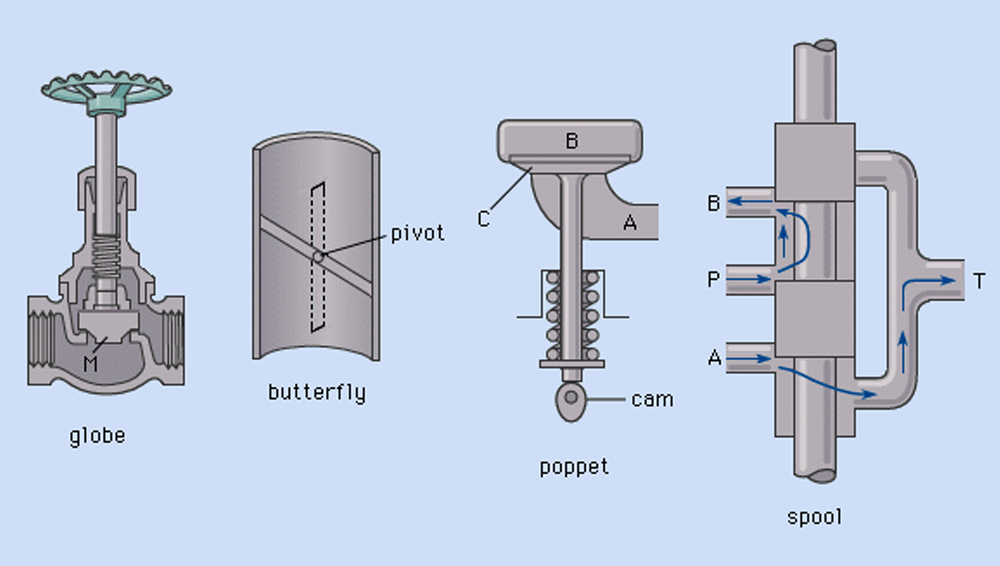

A gate valve is a type of linear motion valve that controls the flow of fluids by lifting or lowering a metal gate. This valve is designed with a wedge-shaped disc, which fits tightly into an aperture within the valve body to regulate fluid flow.

The operation of this valve involves turning the handwheel to raise or lower the gate inside it. When fully open, there is no obstruction to fluid flow through the pipe, and when closed, there is a complete shut-off.

Gate valves are commonly used in industrial applications where high-pressure fluids need to be handled. They can handle larger volumes of fluid than other types of valves such as ball valves and butterfly valves.

One advantage of using gate valves over other types is their ability to provide tight shutoff even after years without being operated. However, they may take longer time to operate compared to other types because they require multiple turns on the handwheel for full closure.

Understanding what a gate valve does helps you determine whether it’s suitable for your application needs.

Pros and Cons of a Gate Valve

Gate valves are commonly used in various industries due to their excellent sealing capabilities and ability to control the flow of fluids. Before you decide on using a gate valve, it’s important to weigh its advantages and disadvantages.

One main advantage of a gate valve is its tight seal which helps prevent leaks. Its simple design also allows for easy maintenance and repair work. Additionally, these valves can handle high-pressure applications making them ideal for use in heavy-duty industries.

However, there are some drawbacks to using gate valves as well. One disadvantage is that they have a slow opening and closing mechanism compared to other valve types like a ball or butterfly valves. This means that sudden changes in flow rate may not be immediately controlled with this type of valve.

Another issue with gate valves is their susceptibility to wear and tear over time, especially when used frequently or subjected to high pressure conditions. In addition, they tend to be bulky and require more space than other types of valves such as globe or needle shut-off valves.

Whether you should use a gate valve depends on your specific needs for fluid regulation within your industry application along with taking into consideration the pros and cons mentioned above.

What are the Best Gate Valves with Pneumatic Actuator?

When it comes to choosing the best gate valve with a pneumatic actuator, there are several options available in the market. Each option has its own unique features and benefits that cater to specific needs.

One of the top choices for a gate valve with a pneumatic actuator is the Bray Series 30/31. This gate valve boasts superior performance and durability, making it ideal for industrial applications where reliability is crucial.

Another great option is the DeZURIK APCO ASU Combination Air Valve. It combines both air release and vacuum breaking functions into one compact unit, making it an excellent choice for water systems.

For those looking for a more cost-effective option, the Bonomi 8E008 Gate Valve offers exceptional value without compromising on quality or performance. It’s easy to install and operates smoothly with minimal maintenance required.

The A-T Controls Pneumatic Actuated Gate Valve also deserves mention as it provides precise flow control that is perfect for regulating fluids in process piping systems. The actuator can be configured on either side of the valve body allowing flexibility during installation.

We have the Mueller Resilient Wedge Gate Valve which has been designed specifically for use in potable water systems. Its durable construction ensures long-lasting service life while providing reliable shut-off capabilities.

When selecting your gate valve with pneumatic actuator, always consider your specific needs and requirements before making your final choice from these top-rated options available today!

How to Choose the Right Gate Valve for Your Project

When it comes to choosing the right gate valve for your project, there are several factors that you need to consider.

Firstly, you need to determine what type of medium the valve will be handling. This could be anything from water and oil to gas or steam. Once you have identified the medium, look for a valve that is specifically designed for that particular application.

Next, consider the pressure and temperature requirements of your project. Make sure that the chosen valve can withstand both high pressures and temperatures without compromising on performance.

Another important factor is size – choose a gate valve with a pneumatic actuator that fits seamlessly into your pipeline system or equipment without causing any disruptions.

It’s also crucial to take into account any specific industry standards or regulations that might apply to your project. Ensure that all valves meet these requirements before making a final decision.

Think about maintenance and repair costs when selecting a gate valve with pneumatic actuator as they should be easy to maintain while still being cost-effective in terms of repairs if needed later down the line.

Conclusion

Choosing the right gate valve with a pneumatic actuator is crucial for any project. With so many options available in the market, it can be overwhelming to make a decision. However, by considering factors such as pressure rating, temperature range, and material compatibility, you can find a valve that will meet your specific needs.

The five gate valves we discussed in this article are among the best options available. Whether you need a valve for water treatment systems or petrochemical plants, these valves offer reliable performance and durability.

Remember that regular maintenance is essential for ensuring the optimal performance of your gate valve with a pneumatic actuator. By following manufacturer guidelines and keeping up with routine inspections and repairs, you can extend the lifespan of your valve and avoid costly downtime.

Investing in high-quality equipment is always worth it when it comes to complex projects that rely on precision engineering. With careful consideration of all factors involved in selecting a new pneumatic actuator gate valve, we hope our guide has been helpful!

Electric actuator gate valves have become increasingly popular in recent years due to their convenience and ease of use. These types of valves are operated by electric motors, which allow for precise control over the flow of materials through a pipeline or other system.

One benefit of electric actuator gate valves is that they can be operated remotely, making them ideal for situations where access may be limited. They also offer greater accuracy than manual or pneumatic valve systems, which can be useful in applications where even small variations in flow rate can have significant impacts on performance.

Another advantage of electric actuator gate valves is their durability and longevity. Because they are powered by electricity rather than mechanical force, these valves tend to experience less wear and tear over time. This means that they require less maintenance and can provide reliable operation over many years.

If you’re looking for a valve system that offers precision control, remote operation capabilities, and long-lasting reliability, an electric actuator gate valve might be just what you need!

Although manual actuator gate valves offer simplicity and reliability in operation, they may not be suitable for applications requiring rapid response times or frequent use due to their limitations when compared with other types of actuators.