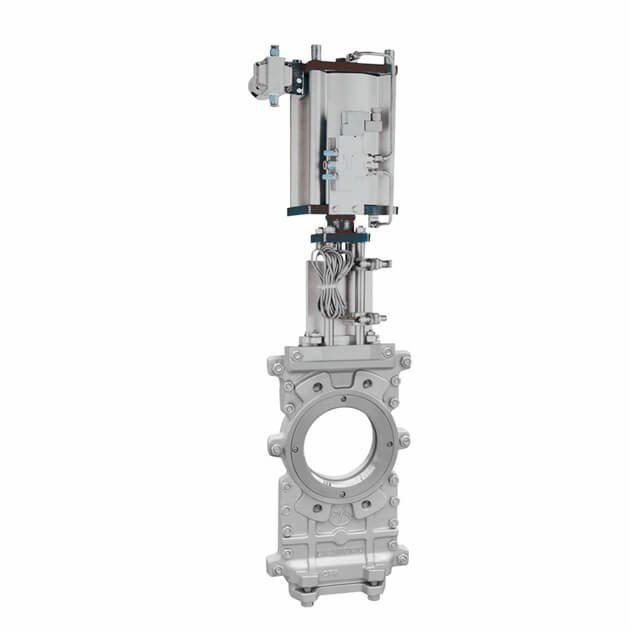

GMK Knife Gate Valve

In systems with a high concentration of suspended particles, knife gate valves are ideally suited for on/off and isolation duties. Slurry, along with viscous, corrosive, and abrasive media, are all well-suited for use with knife gate valves. When fully open, the pressure loss across the valves is minimal, and the valves themselves are lightweight, simple to operate, and inexpensive. Knife gate valves can withstand extreme conditions and are equipped with a sharp blade to easily pass-through thick liquids. They excel in situations where corrosion is a concern, such as those involving wastewater. Therefore, it is preferable to have a knife made of acid-proof stainless steel in addition to a valve design optimized for slurry medium, as this makes it less vulnerable to problems caused by corrosion and, as a result, it requires less regular maintenance or even replacement. Unless specifically built for such a purpose, knife gate valves should only be used in the fully open or fully closed positions, never to modulate flow. Vibrations caused by fluid pressure against a partially closed gate wear away at the disc and seat over time. The water hammer can be mitigated thanks to the knife gate valves’ slow opening and closing mechanisms.

- Size:2″-48″

- Pressure:150LB, 300LB

- Material:WCB, LCB, LCC, WC6, WC9, C5, C12, C12A, CF8, CF8M, CF3, CF3M, CN7M, Alloy 20, B148,UB6, Hastelloy C etc

- Connection:Flanges, RTJ flange, wafer, lugged

- Operation:Handwheel, wormgear, gearbox, pneumatic actuator