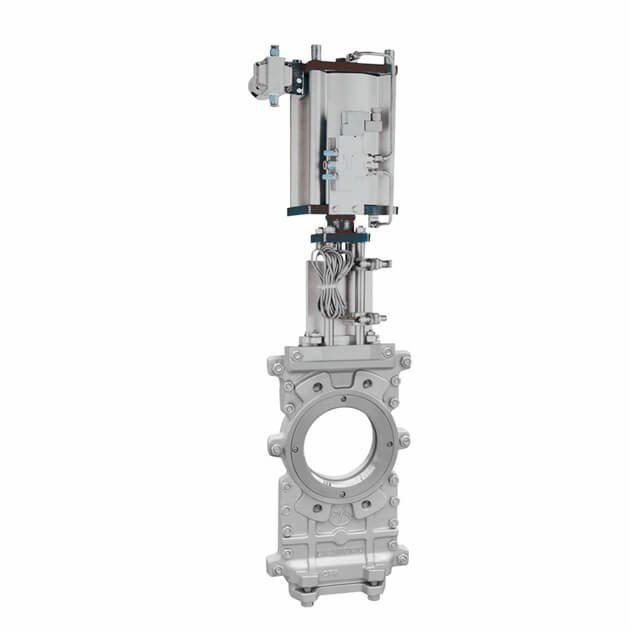

GMK Knife Gate Valve with Pneumatic Actuator

GMK offers a Knife Gate Valve with Pneumatic Actuator. To better sever the process media, the closing membrane of a knife gate valve, which is a linear valve, is sharpened (such as slurry). As the gate moves from open to closed within the valve body, it is cleaned by scrapers that are attached to the stem. You can find them in wafer, lug, and flange connections, and they can be operated manually or automatically (using a knife gate valve actuator). Knife gate valves have several uses, including those requiring isolation and those requiring precise control. However, valve trims need to be tailored to each individual system in order to deliver adequate control characteristics. Traditional knife gate valves, such as those made of robust material or with a metal seat, are primarily intended for fluid isolation because of their weak control qualities. Their ‘blade-like’ gate shape is particularly well-suited to situations in which the process media is extremely thick or has a high concentration of solids. In addition to the benefits of the reduced internal area being in contact with highly abrasive process media, their design also features a short face-to-face dimension.

- Size:DN 50~600mm NPS 2”-24”

- Face to face:MSS SP-81

- Flange connection :GB/T 9113.1, JB/T 79.1, HG 20592, ASME B 16.5, EN1092-1 (other connections on request)