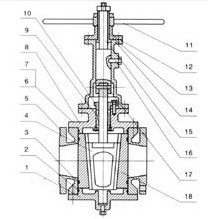

GMK Orbit Plug Valve / DBB PLUG VALVE

Orbit plug valves are utilized in a wide variety of industries, including the oil and gas sector, the chemical and fertilizer sector, the power sector, and many others. The product is attractive and functional in design as well as being of high quality. The rings of seals that surround the disc of the valve are what actually do the sealing. Wallow-tailed sink and fixed sealing rings provide specialized protection.

It’s easier to set up and use than similar products because of its unique bidirectional flow. To accommodate a wide range of technical requirements, we offer a wide range of part materials and flange sizes that can be reasonably configured based on actual operation conditions or customer specifications. When fully open, the valve’s plug channel lines up with the valve body’s, allowing for the most efficient pressure drop possible. When the handwheel is turned, the plug rotates in the direction of closure while simultaneously drafting the valve disc’s rotation by 90 degrees; when the handwheel is turned further, the plug is pressed down, causing the valve disc to open on both sides, bringing it into close proximity with the valve seat. First, the plug moves upward, separating the valve disc from the valve seat; then, when the handwheel is cranked further, the valve disc is rotated by 90 degrees, driven by the plug, and lastly, the plug’s channel lines up with the valve body’s channel, fully opening the valve. The soft seal applied for sealing ensures that there will be no leakage in the process of shutting the valve, and the separation of the valve disc and valve seat means that there is no friction and, consequently, no abrasion of the sealing face during opening and closing.

- Size:1/2″-24″

- Pressure:150LB, 300LB, 600LB, 900LB

- Material:WCB, LCB, LCC, WC6, WC9, C5, C12, C12A, CF8, CF8M, CF3, CF3M, CN7M, Alloy 20, B148, UB6 904l, Hastelloy C etc

- Connection:Flange

- Operate:Handwheel, wormgear, pneumatic actuator