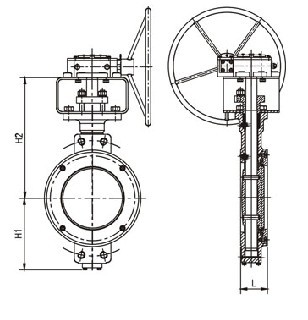

GMK High Performance Butterfly Valve

A GMK high-performance butterfly valve is also known as a double-offset butterfly valve. Double Offset refers to the fact that the disc of a High-Performance Butterfly Valve is not centered on the seat. This setup has the disc eccentric or displaced, relative to the valve seat. The disc deviates away from the user rather than across the seat when it begins to rotate. Sealing is aided in this design by the pressure from the line itself. Offset butterfly valves can be used in high-pressure systems, such as those used for heating, ventilation, and air conditioning, thanks to this design characteristic. Its seats are typically made of PTFE or acrylic, while metal seats are also available for use with fire testing protocols such as API 607. The polymer seat of a double offset butterfly valve is typically PTFE, and the metal backing is there to prevent fires. Metal-to-metal chairs are also on the market, and they might offer better sealing quality and tolerate slightly greater temperatures.

- Size:DN50-DN2000

- Rating:150LB-900LB

- Material:Cast iron, ductile iron, WCB, LCB, LCC, WC5, WC6, WC9, CF8, CF8M, CF3, CF3M, B148, UB6, CN7M, CK20, etc

- Connection:Wafer type, lug type, flange

- Operate:Handwheel, gearbox, pneumatic