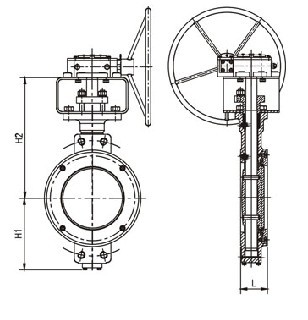

GMK Double Eccentric Butterfly Valve

Engineered with two eccentric butterfly valves, our GMK double eccentric butterfly valves are built to last. The optimized seal design, the corrosion-protected shaft end zones, and the slanted, securely fastened disc all set new benchmarks in the industry. After the disc has opened a small amount, the tension is released, reducing the amount of wear on the disc seal. In addition, the design ensures low operating torques by reducing the compression of the sealing. A key and keyway are used to join the disc to the shaft. To counteract the jiggling that can occur due to the combination of fluid velocity and the inherent slack in the key and keyway, two set screws are employed to keep the key firmly in place. Due to its large size, the disc is fastened by two stainless steel drive dowels, with a key and keyway as a backup. The integral seat design incorporates a ductile iron seat that has been machined and coated with epoxy. With this stainless-steel seat design, leaks under the seat ring are prevented with a stainless-steel seat ring that can be replaced and is sealed with an O-ring. The disc seal was designed to keep the fixation in place securely, making it an excellent choice for this application. Thanks to the high quality of the rubber, it may be used in fewer quantities, resulting in less closing torque.

- Size:2″-80″

- Pressure:150LB, 300LB, 600LB, 900LB

- Material:Cast iron, ductile iron, WCB, LCB, LCC, WC5, WC6, WC9, CF8, CF8M, CF3, CF3M, B148 ect

- Connection:Wafer type, lug type, flange, BW

- Operate:Handwheel, gearbox, penumatic actuator