Do you have a clogged sink or toilet? Did you know that it’s possible to fix this yourself without calling a professional? In this blog post, we will show you how to install a bellow seal globe valve, which is a common solution for many drain and drainpipe problems. By following our simple instructions, you will be able to fix your issue in no time at all.

What is a Bellow Seal Globe Valve?

A bleeder valve is a type of relief valve that helps relieve air pressure in a system. They are also known as globe valves, bleeder screws, or simply bleeder valves. When the system reaches equilibrium, the air pressure in the line will be equal on both sides of the valve and the relief will be maximized. Bleeder valves are used to release air from systems such as pipelines, manifolds, and other pressurized areas. They come in a variety of styles and sizes to meet your specific needs.

How to Install a Bellow Seal Globe Valve

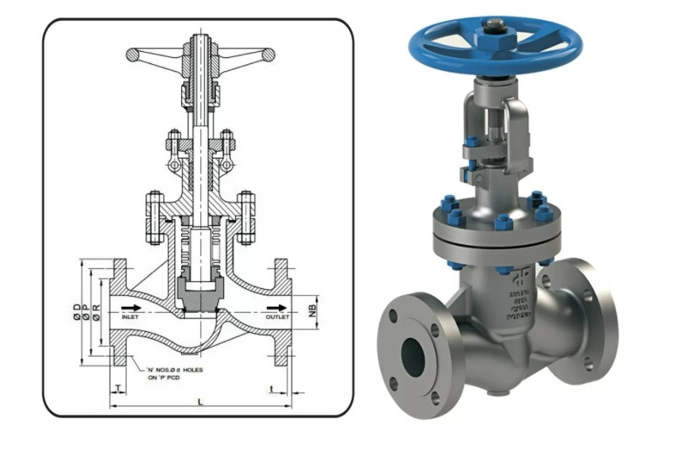

Bellow seal globe valves are a type of valve that is used to control the flow of water in a system. They are made of metal and are designed to operate using a ball-and-socket joint. To install a bottom seal globe valve,

you will need the following items:

1. A ball-and-socket joint fitting

2. A wrench

3. A pipe cutter or hacksaw

4. A hammer and nails

5. A basin or bucket

6. Waterproof adhesive (optional)

7. Pipe cleaner (optional)

8. An oil-based lubricant (optional)

9. Socket set and screwdriver

10. Hammer and nails

11. Basin or bucket

Steps:

1 – Shut off the water supply to the area you will be working in by turning off the main valve at the meter or turning off the secondary shutoff valve if there is one in use.

2 – Remove any existing floor or drainage pipes near where you will be installing the valve by either breaking them free with a pipe cutter or hammer and nails or simply pulling them out when they become loose due to wear and tear over time

3 – Get your socket set ready by removing the cap on one end of it and unscrewing it until it becomes free from its retaining nut

4 – Fit your socket onto one end of the pipe cutter, being sure that it is situated so that its flat edge is resting against one side of the pipe cutter’s cutting edge

5 – Use the wrench to tighten the socket retaining nut until it is tight against the pipe cutter’s cutting edge

6 – Fit the other end of the pipe cutter onto the end of the valve stem that you will be using and screw on the socket retaining nut until it is tight against the valve stem

Steps:

7 – Carefully cut through both ends of the pipe with the pipe cutter, being sure to leave a few inches of pipe attached at either end for easy handling later on

8 – Remove and discard any ruined sections of pipe from your work area by hammering them free with a hammer and nails or by using a basin or bucket to catch them

9 – Unscrew the old ball-and-socket joint fitting from its housing by removing its two screws (one at each end)

10 – Be sure to remove all of the old adhesive and sealant from both surfaces of the new ball-and-socket joint fitting by using a hose or spray bottle filled with water and then spraying it directly onto the fitting’s surfaces until they are clean and free of adhesive and sealant

11 – Fit one end of the new ball-and-socket joint fitting into the hole in the old valve housing and screw it into place by using the screws that were removed in step 9

12 – Replace the old ball-and-socket joint fitting with the new one by reversing the steps that were taken to install it

13 – Turn on the water supply to the area you just worked in and check to see if the valve is functioning correctly by opening and closing it several times

What could happen if the valve is not installed correctly?

If the installed valve is not properly seated and flushes with the wall of the pot, water can leak past it and cause corrosion and Maybe even a pipe burst.

To prevent this from happening, make sure to install the valve correctly as shown in the diagram below: The valve should be installed at an angle of 45 degrees so that its bottom is flush with the pot’s wall. If the installation is done incorrectly, water can leak past the valve and corrode pipes.

What are the benefits of installing a Bellow Seal Globe Valve?

A ball-valve Globe valve is a type of valve that uses a ball to close the valve, making it particularly suitable for applications in which a high degree of accuracy and reliability are required. These valves are often used in petrochemical, pharmaceutical, food processing, and other industries where the purity and quality of the products are important.

The benefits of installing a ball-valve Globe valve include:

– Precision: The ball-valve Globe valve features precision mechanics that allow for reliable operation. This is essential for applications such as petroleum production, where precise measurements are required.

– No wear and tear: Ball-valve Globe valves don’t experience the wear and tear that can occur with other types of valves. This is due to their precision mechanics and the lack of moving parts. As a result, these valves can last longer without needing to be replaced or repaired.

– Reduced maintenance: Because ball-valve Globe valves don’t require any lubrication or maintenance, they’re less likely to require repairs or replacements. This means less time spent on maintenance tasks, which can free up resources for other tasks.

What is a Globe Valve and How Does It Work?

A globe valve is a type of valve that uses a ball or globe seal instead of a keyed or threaded seal. This type of valve is used in applications where it is difficult or impossible to install a traditional valve, such as in applications with tight spaces or high pressure. Globe valves are also commonly used in air conditioning and refrigeration systems.

To use a globe valve, you first need to open the valve completely by rotating the handle. Then, you place the ball or globe on the seat and close the handle so that the ball seals against the seat. To open the valve, you rotate the handle again until the ball falls off of the seat.

Tools You’ll Need to Install a Globe Valve

To install a globe valve, you’ll need the following tools:

-Screwdriver

-Socket wrench

-Needle nose pliers

-Hammer

-Tape measure

-Paint or sealant

Tips for Proper Maintenance

To properly maintain your globe valve, follow these tips:

1. Inspect the globe valve for wear and tear. If it appears to be in bad shape, replace it.

2. Clean the globe valve with a damp cloth every time you use it.

3. Check the Globe Valve Gasket for wear or tears before replacing it.

Conclusion

Installation of a below-floor bellow seal globe valve can be a tricky job, but with the right tools and some patience, it can be done easily. Make sure to read the instructions carefully before starting, and use the correct-sized wrench for the bolt that needs to be removed. If all goes well, you will now have peace of mind knowing that your house is protected against flooding in case of an emergency. Thanks for reading!