The Benefits of Using a Pure Nickel Ball Valve

When it comes to fluid control, ball valves are the go-to solution for many industries. And if you’re looking for a durable and corrosion-resistant material for your ball valve, pure nickel is an excellent choice. Pure nickel ball valves offer numerous benefits that make them perfect for various applications, from chemical processing plants to oil refineries. In this blog post, we’ll explore why pure nickel is the ideal material for ball valves and discuss the advantages of using a pure nickel ball valve over other metals like stainless steel or brass. We’ll also cover different types of pure nickel ball valves available in the market today and provide tips on how to select the right one suitable for your specific application. Read on to learn more about how a simple switch to a pure nickel ball valve can make all the difference!

Pure Nickel is the Ideal Material for Ball Valves

Pure nickel is an excellent material for ball valves due to its high resistance to corrosion and extreme temperatures. Unlike brass or stainless steel, pure nickel has exceptional mechanical properties that make it ideal for use in harsh environments where other materials would fail.

One of the significant advantages of using pure nickel in ball valves is its non-reactive nature with many chemicals, making it perfect for handling corrosive fluids. This characteristic ensures that the valve remains functional even after prolonged exposure to aggressive substances.

Another reason why pure nickel is a suitable material for ball valves is its ability to withstand extreme temperatures without degrading over time. Pure Nickel can resist oxidation at high temperatures and maintain its mechanical strength even under severe conditions, giving you peace of mind knowing your valve will operate as intended.

When choosing a ball valve material, considering the specific application’s requirements is essential. However, if you need a durable and reliable solution that can handle harsh chemicals and extreme temperature fluctuations while remaining cost-effective in the long run; then investing in a pure nickel ball valve may be worth considering!

The Benefits of Using a Pure Nickel Ball Valve

When it comes to selecting the right valve for an application, using a pure nickel ball valve can offer several benefits. One of the biggest advantages is that pure nickel is highly resistant to corrosion, making it an ideal material for valves that come into contact with corrosive liquids or gases.

Pure nickel ball valves also have excellent heat resistance and can withstand high temperatures without degrading or warping. This makes them suitable for use in applications where there are extreme temperature fluctuations.

Another benefit of using a pure nickel ball valve is its durability. Pure nickel has a high hardness level, which means that it can resist wear and tear even after extended periods of use. Additionally, because these valves are made from a single piece of metal, they have fewer points of weakness than other types of valves.

Pure nickel ball valves are easy to maintain and repair as needed. Because they are simple in design and construction, any necessary repairs or maintenance work can be completed quickly and easily without requiring specialized tools or knowledge.

If you need a reliable valve solution for your industrial process or application, consider using a pure nickel ball valve due to its corrosion resistance, durability and ease-of-maintenance features.

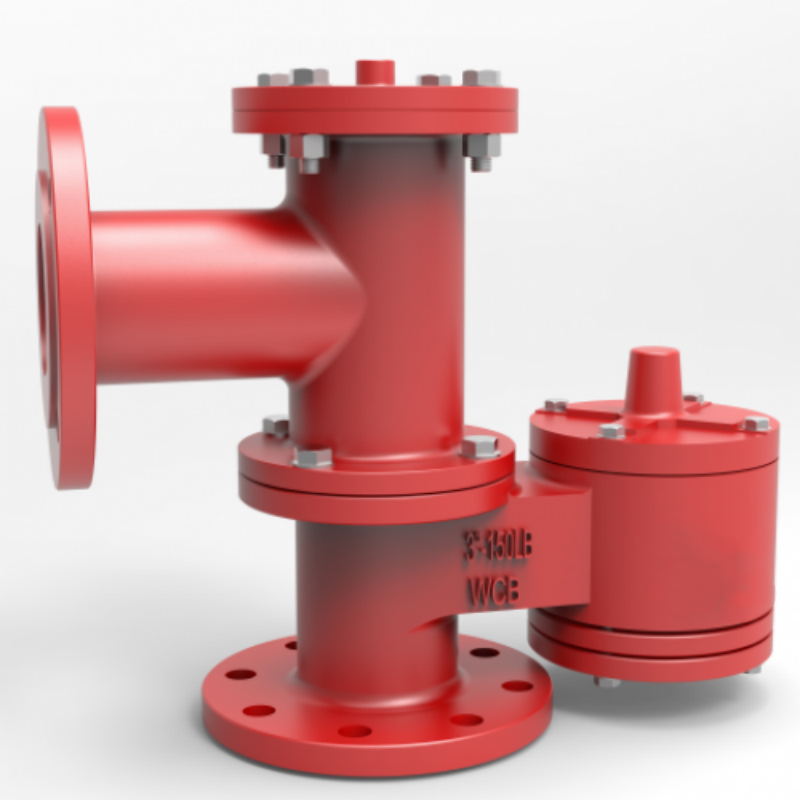

The Different Types of Pure Nickel Ball Valves

Pure nickel ball valves come in different variations, each designed to cater to specific applications. One type of pure nickel ball valve is the full-port design, which features a larger internal diameter for maximum flow capacity. This type is ideal for applications that require high flow rates.

Another variation is the reduced-port design, which has a smaller internal diameter and is commonly used in low-flow situations. It’s also more cost-effective than its full-port counterpart.

The three-piece design offers greater flexibility in terms of maintenance and repair since it can be disassembled easily without removing the entire valve from the pipeline. Additionally, this design provides easy access to the valve’s internals during cleaning or replacement.

Trunnion-mounted ball valves have their ball supported by trunnions on both sides instead of just one side like floating-ball designs. They’re best suited for high-pressure systems where tight shut-off is critical.

Multiport configuration allows for multiple ports within a single valve body, enabling various functions such as diverting or mixing media flows. These types are often used when space is limited or when there’s a need to minimize piping connections.

Understanding the different types of pure nickel ball valves helps you select the right one for your application based on factors such as pressure requirements and installation constraints.

How to Select the Right Pure Nickel Ball Valve for Your Application

When it comes to selecting the right pure nickel ball valve for your application, there are a few key factors to consider. The first thing you need to determine is the purpose of your valve and the conditions it will be exposed to.

Next, you need to think about the size of your valve and its connection type. It’s important that you choose a valve with the appropriate size and connection for your system in order to ensure optimal performance.

You also want to take into account any specific features or requirements unique to your application. For example, if you’re working with highly corrosive materials, you may want to look for a valve with enhanced corrosion resistance properties.

Another important consideration when choosing a pure nickel ball valve is the temperature range it can handle. You’ll want a valve that can operate effectively within the temperature range of your system without risking damage or reduced performance.

Don’t forget about industry regulations and standards that may apply in your particular field. Make sure any valves you select meet all necessary compliance requirements for safety and functionality.

By taking these factors into account, you can confidently select the perfect pure nickel ball valve for your specific application needs.

Conclusion

To sum it up, using a pure nickel ball valve has numerous benefits that make it the ideal material for various applications. Whether you need to control the flow of corrosive or high-temperature fluids, a pure nickel ball valve can provide reliable and long-lasting performance.

When selecting a pure nickel ball valve for your application, consider factors such as pressure rating, temperature range, size, and end connections. It’s essential to choose a valve that meets your specific needs to ensure optimal performance and efficiency.

Investing in a high-quality pure nickel ball valve will not only save you time and money but also enhance the safety and reliability of your system. Remember always to consult with an expert if you have any doubts about which type of valve is best suited for your application.