Wouldn’t it be great if you could just turn on the faucet and have a steady flow of water without having to deal with pesky drips and water spots? Well, that’s what water pressure is for—to provide a consistent flow of water.

In order to make sure your home has the pressure it needs, you need a top entry ball valve. This is a valve that sits inside the pipe itself, instead of at the surface where water flows in and out.

This guide will take you through all the important details about these valves, from types to features to installation. So whether you’re looking for a new faucet or just want to keep your home properly pressurized, read on for an in-depth guide on top entry ball valves.

What is a Top Entry Ball Valve?

Top entry ball valves are often used in industrial and agricultural applications to control the flow of water or other fluids. They are also common in swimming pools because they provide a quick, controllable way to adjust the water level.

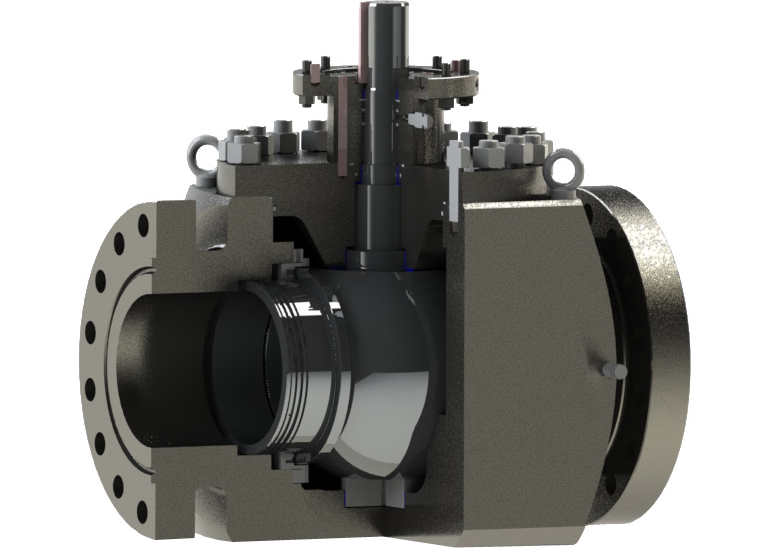

A top entry ball valve is a type of valve that has a flat surface on top. This surface is typically made out of metal or plastic and is fitted with a movable gate that sits above the flat surface. The gate can be opened and closed by hand or via a mechanism, such as a spring, that pulls it down over the top of the valve. When the gate is closed, it blocks the flow of fluid through the valve.

To open the gate, someone needs to pull it down using whatever mechanism is attached to it. This usually involves using their hands or some kind of tool. Once the gate is open, fluid can flow freely through the valve.

Top entry ball valves come in different sizes and styles, depending on their specific application. They are typically designed for quick and easy operation, which is why they’re popular for industrial and agricultural applications.

How Top Entry Ball Valves Work

A top entry ball valve is a type of valve used in water, gas, and steam systems. They are most commonly used for controlling the flow of water or gas. The name comes from the fact that the valve opens at the top of the pipe instead of the bottom like a traditional valve. This makes it easier to control the flow of fluid.

Top entry ball valves come in a variety of styles and sizes. Some common types include union ball valves, gate valves, and butterfly valves. Each has its own advantages and disadvantages, so it’s important to choose one that will fit your specific needs.

Union Ball Valves

Union ball valves are usually the simplest type of top-entry ball valve and are typically used for small applications such as water lines or heating systems. They consist of two chambers connected by a movable union fitting. When you turn on the water supply, the pressure in the first chamber causes the union fitting to move open, allowing water to flow into the second chamber. To shut off the water supply, you simply turn off the power to both chambers.

One downside of union ball valves is that they can be difficult to flush if clogged with sediment or debris. Also, they don’t have any built-in protections against overpressure or bursting. For these reasons, union ball valves are typically only used in low-pressure applications where reliability is not an issue.

Gate Valves

Gate valves are similar to union ball valves in that they consist of two chambers connected by a movable union fitting. The main difference is that gate valves have a gate, or door, that opens and closes to control the flow of fluid. When you turn on the water supply, the pressure in the first chamber causes the gate to move open, allowing water to flow into the second chamber. To shut off the water supply, you simply close the gate.

One advantage of gate valves is that they’re easier to flush than union ball valves. They also have built-in protections against overpressure and bursting. However, they do require more space than union ball valves and can be more difficult to install.

Butterfly Valves

Butterfly valves are one of the most popular types of top-entry ball valves because of their versatility. They can be used for both water and gas systems, and they offer several advantages over other types of ball valves. For example, butterfly valves are easy to install and maintain because they don’t require any special tools or skills. They also have low operating costs because they don’t need any extra pressure to function.

However, butterfly valves aren’t perfect. One downside is that they can be difficult to flush if clogged with sediment

Types of Entry Ball Valves

There are many types of ball valves, but the two most common are check valves and gate valves. Check valves are simple devices that prevent water from flowing backward through a pipe when the valve is open. Gate valves are more complex devices that allow water to flow in one direction or the other depending on the position of the gate.

How to Choose the Right Entry Ball Valve for Your Application

Choosing the right entry ball valve for your application can be a daunting task. But with a little research and some help from our experts, you’ll be able to find the perfect one for your needs.

When choosing an entry ball valve, you first need to consider the application. Some valves are designed for use in water distribution systems, while others are better suited for industrial or agricultural applications.

Once you have determined the type of ball valve that best suits your needs, it’s important to consider the features that are important to you. Some of the most common features include pressure ratings, flow rates, and port sizes.

In addition to these features, it’s also important to consider how easy the valve is to operate. Many ball valves come with user-friendly features like electronic control panels or quick-release fittings. Finally, make sure to budget carefully when shopping for an entry ball valve – not all models are created equal. You’ll want to choose a model that fits your specific needs and budget constraints.

Installation Tips for Entry Ball Valves

Installing an entry ball valve is a simple process that can save you time and hassle. Here are some installation tips to get you started:

1. Read the manufacturer’s instructions. Many entry ball valves come with detailed installation instructions, which will help you get the job done correctly.

2. Clean the area where the valve will be installed. This will help prevent clogging and ensure a smooth transition when installing the valve.

3. Mark the location of the valve on the surface where it will be installed using a pencil or a piece of paper. This will help you locate the valve during installation later on.

4. Remove any old molding or trim around the perimeter of the opening where the valve will be installed. This will give you better access to install the valve correctly and reduce the chances of injury in case of an accident.

5. Unscrew the existing knob or handle from the faucet and remove it if present (it may not need to be removed). If there is no knob or handle, simply unscrew the stem from the faucet housing until it comes free from its mountings (usually this requires twisting counterclockwise). Be sure to save both parts!

6. Inspect and clean any areas around threads on a new fixture that might collect mineral deposits over time (this includes all threaded assembly fittings such as washers, nuts, bolts, etc.). Apply sealant where necessary (available at hardware stores) to prevent water leakage.

7. Thread the new fixture onto the threads on the old one so that the mounting holes line up. If there are any washers or other mounting accessories present, install them now.

8. Insert the bolt(s) and/or washer(s) into the corresponding mounting holes on the fixture and tighten using a wrench or an adjustable wrench. Be sure to use enough torque to prevent the fixture from turning during installation.

9. Install the new knob or handle if desired and tighten using a wrench or an adjustable wrench. Be sure to use enough torque to prevent the fixture from turning during installation.

Applications for Entry Ball Valves

Entry ball valves are typically used in situations where a small valve must be opened quickly and repeatedly, such as in water pumps or gas control valves. In these applications, the valve must remain open for a very short time so that the fluid can flow freely.

There are many types of entry ball valves, but all share certain features. All have a stem that screws into the body of the valve, and they all have a movable gate at the top. The gate is usually held in place by a spring, and it can be opened and closed by rotating it relative to the stem.

Entry ball valves come in many shapes and sizes, but most common are those with round stems and oval gates. They can also be found with flat stems and triangular gates, but these are less common.

One important feature of entry ball valves is their discharge opening. This is the area on the side of the valve where fluid exits the valve. It is important to choose an opening size that will allow fluid to flow freely without creating pressure waves or cavitation bubbles inside the system.

Another important factor to consider when selecting an entry ball valve is its stroke rating. This is how much distance the gate can move before resistance builds up and causes it to stop moving. The greater the stroke rating, the faster the gate can travel before stopping.

Selection of an Entry Ball Valve

Choosing the right entry ball valve for your application can be a daunting task. In this article, we will provide a comprehensive guide on selecting the right ball valve for your needs.

First and foremost, it is important to determine what type of valve you need. There are three types of ball valves: butterfly, diaphragm, and check valves. Butterfly valves have hinged flaps that open and close the flow of water. Diaphragm valves have a rubber or metal disk that moves up and down to control water flow. Check valves are typically used in pipelines where there is precise control over water pressure and flow rates.

Once you know what type of ball valve you need, it is important to consider the size and capacity of your application. Ball valves come in both standard and metric sizes. Always verify the size before making your purchase so that you don’t end up with a useless piece of equipment. Ball valves also come in different capacities from 1/4 inch to 2 inches in diameter and 10 inches to 50 feet in length. Make sure to choose the correct size for your application so that it doesn’t overflow or kink during operation.

Next, it is important to consider how you will use the ball valve. Will it be operated manually or automatically? Will it be used as an upstream or downstream valve? If automatic operation is required, make sure that the ball valve has an alarm system so that you will be alerted if there is any problem with the valve.

Finally, it is important to consider the cost and warranty of the ball valve. Always compare prices and warranties before making your purchase.

Maintenance and Repair of an Entry Ball Valve

Entry ball valves are a common device used in water distribution systems. These valves allow water to flow through them in one direction only, and are typically closed off by a gate when the system is not in use.

Maintenance and Repair of an Entry Ball Valve

Entry ball valves require regular maintenance and repairs to keep them operating correctly. Failure to do so can result in serious water leaks or even system failure. This section will outline some of the most common problems that entry ball valves may experience, as well as the steps necessary for their proper repair.

Problems with Entry Ball Valves

1. Leaks: One of the most common problems with entry ball valves is leaking water. Unfortunately, this can happen for a number of reasons, including worn seals and deteriorated components. To prevent leaks, it’s important to inspect and maintain your valve regularly.

2. Gate Closure: Another issue that can cause entry ball valves to fail is improper gate closure. If the gate fails to close completely, water will escape from the valve and potentially damage equipment downstream of it. To avoid this problem, make sure to check your gates every time you turn your system on and off.

3. jammed gates: If your gates become jammed due to debris or other obstruction, they may not be able to close properly which can lead to leakage or malfunctions elsewhere in your system. In order to fix this issue, you’ll need to remove any obstruction or debris. They also don’t have any built-in protections against overpressure or bursting.

Overall, top entry ball valves are versatile and affordable tools that can be used in a variety of applications. It’s important to choose the right one for your specific needs, so consult with a qualified professional before making any decisions.

Conclusion

If you’re looking to upgrade your irrigation system, then you’ll want to consider installing a top entry ball valve. This type of valve is much more efficient than traditional valves, and it can reduce water usage by up to 50 percent. In this comprehensive guide, we’ll walk you through the steps necessary to install a top entry ball valve, and we’ll provide tips on how to maximize its efficiency. So whether you’re in the market for a new irrigation system or just want to improve your current one, make sure to check out our top entry ball valve guide!