Welcome to our blog post on why you should replace your metal-to-metal seat ball valve! Are you experiencing leaks, excessive wear, and tear, or difficulty in operation with your current valve? If so, it may be time for an upgrade. In this article, we will explain what a seat ball valve is, why metal-to-metal seat valves are problematic, the benefits of replacing your old valve, and how to do so. Keep reading to learn everything you need to know about upgrading your mechanical system with a new and improved seat ball valve!

What is a seat ball valve?

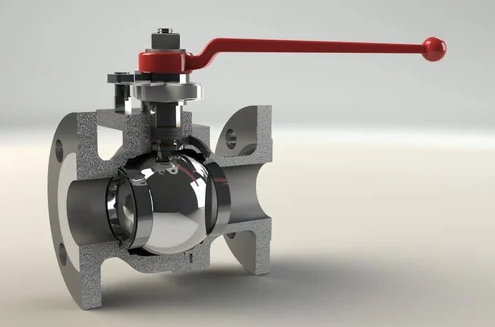

A seat ball valve is a mechanical device used to control the flow of liquids or gases in a pipeline. It consists of a spherical ball with a hole in its center and two seats, one on either side, that form seal rings around the ball.

When the valve is open, the fluid flows through the hole in the ball and out through the other end. When closed, the seats compress against each other to prevent any fluid from passing through.

Seat ball valves can be operated manually or automatically using an actuator. They are commonly used in industrial processes such as oil refineries, chemical plants and water treatment facilities due to their ability to handle high pressures and temperatures.

There are different types of seat ball valves available including metal seated valves which have metal-to-metal contact between their components, soft-seated valves which use softer materials for sealing like rubber or Teflon®, among others. The choice depends on your specific application requirements including temperature range, pressure rating and media type.

Why metal to metal seat ball valves are bad

Metal to metal seat ball valves may seem like a reliable choice for controlling the flow of fluids in industrial applications, but they actually come with a lot of drawbacks. One major problem is that they tend to wear out quickly due to constant friction between the metal surfaces.

This can cause leaks and inefficiencies, leading to costly downtime and repairs. Another issue with metal to metal seat ball valves is that they require more maintenance compared to other types of valve seats.

In addition, when using these valves in high-temperature or high-pressure environments, their performance tends to deteriorate rapidly as the heat causes them to expand and contract which leads them towards leakage over time.

Moreover, Metal-to-metal seating areas also have limited self-sealing ability making it difficult for any particles trapped between the seals while closing down causing difficulty during reopening procedures.

If you want your fluid control system running efficiently without frequent breakdowns or regular maintenance routines then replacing your old metal-to-metal seat ball valve with a newer type designed specifically for different applications might be worth considering.

The benefits of replacing your seat ball valve

Replacing your metal to metal seat ball valve can bring you several benefits that you might not even be aware of. Firstly, replacing this type of valve with a soft seated one will reduce the amount of noise and vibrations in your system. This is because when two metal surfaces rub against each other, they create friction and consequently cause noise.

Secondly, using a soft seated valve can help prevent leakage as it creates a better seal between the ball and the seats. These valves are also easier to maintain compared to their metal counterparts since they require less lubrication.

Thirdly, replacing your old valve with a new one can improve efficiency by reducing pressure drops across the system. Metal to metal seat ball valves have higher resistance which leads to increased energy consumption whereas soft seated valves have lower resistance meaning less energy loss.

Upgrading your valve can increase its lifespan thereby saving you money in the long run. Soft-seated valves tend to last longer than their metal counterparts due to reduced wear and tear caused by friction.

In summary, there are many advantages that come with replacing your old or worn-out seat ball valve with a new soft-seated one including improved efficiency, reduced noise levels and maintenance costs while increasing longevity at no extra cost.

How to replace a seat ball valve

Replacing a seat ball valve may seem like a daunting task, but it can be done with the right tools and knowledge. Before starting, make sure to turn off the water supply and relieve any pressure in the system.

First, remove any bolts or nuts that are holding the valve in place. This will allow you to take out the old valve from its housing. Be careful not to damage any surrounding pipes or fittings during this step.

Next, clean out the area where the old valve was located. This will ensure that there is no debris left behind that could cause issues with your new valve.

Once everything is cleaned up, install your new seat ball valve into its housing. Make sure all connections are tight and secure before turning on your water supply again.

Test out your new valve by turning on the water supply and checking for leaks or other issues. If everything looks good, then you’ve successfully replaced your metal to metal seat ball valve!

Conclusion

To sum up, replacing your metal to metal seat ball valve can bring numerous benefits to your industrial operations. These valves may seem sturdy and durable at first glance, but they are prone to leakage and failure in the long run. By switching to soft-seated or lined ball valves, you can enjoy better sealing performance, reduced downtime, lower maintenance costs, and increased safety for workers and the environment.

Replacing a seat ball valve might seem daunting at first, but with proper planning and execution, it can be a simple process that yields significant results. Whether you need help selecting the right type of valve or installing it correctly on your piping system, qualified professionals can assist you every step of the way.

Ultimately, investing in high-quality valves is an essential part of ensuring optimal efficiency and reliability for your industrial processes. By staying informed about new technologies and best practices in valve selection and maintenance, you can stay ahead of the game while preventing costly mistakes down the line. So why wait? Replace your metal to metal seat ball valve today – Your business will thank you!