Our Closed Spring Loaded Low Lift Type High Pressure Safety Valves are utilized for corrosive equipment and pipelines. A41Y-160/320 kinds are utilized for equipment and pipelines that function below 200°C. A41Y-160P/320P and A41Y-160R/320R are utilized for corrosive gas and liquid equipment and pipelines below 200°C. Add pressure protection. A42Y-C is utilized for air, petroleum gas, liquid, and other low-temperature equipment and pipelines. A42Y-P and A42Y-R are utilized for corrosive equipment and pipelines. What’s below 200°C? A48Y is used in steam and air equipment and pipes up to 350. Use pressure-protection equipment. A48Y type is used for steam and air equipment and pipelines with temperatures below 350°C. A44Y type is utilized for air and petroleum gas operating temperatures less than 300°C equipment and pipelines. Add pressure protection devices.

Benefits:

- It uses a pressure self-sealing design and is joined at both ends by welding.

- To compensate for the difference in pressure between the intake and exit, it uses an electronic bypass valve.

- The method for shutting it uses a parallel pair of flashboards. To avoid dangerous strain during opening and shutting, the valve is sealed not by a wedge but by medium pressure.

- The sealing face has been built up using a strong alloy based on cobalt, which gives it great temperature resistance, corrosion resistance, abrasion resistance, and long service life.

- Valve stem surfaces that have been treated against corrosion and nitrogenization have improved corrosion resistance, abrasion resistance, and stuffing box sealing.

|

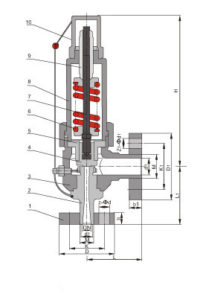

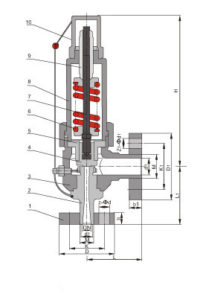

NO.

|

Name of part

|

A41Y-160

A41Y-320 Materials

|

A41Y-160P

A41Y-320P Materials

|

A41Y-160R A41Y-320R Materials

|

|

1

|

Flange

|

35/35CrMoA

|

2Cr13

|

1Cr18Ni9Ti

|

|

2

|

Nozzle

|

2Cr13

|

1Cr18Ni9Ti

|

1Cr18Ni12Mo2Ti

|

|

3

|

Body

|

35/40

|

1Cr18Ni9Ti

|

1Cr18Ni12Mo2Ti

|

|

4

|

Disc

|

2Cr13

|

1Cr18Ni9Ti

|

1Cr18Ni12Mo2Ti

|

|

5

|

Guide Sleeve

|

2Cr13

|

1Cr18Ni9Ti

|

1Cr18Ni12Mo2Ti

|

|

6

|

Spring

|

50CrVA

|

50CrVA Coated Teflon

|

50CrVA Coated Teflon

|

|

7

|

Stem

|

2Cr13

|

1Cr18Ni9Ti

|

1Cr18Ni12Mo2Ti

|

|

8

|

Bonnet

|

ZG230-450

|

1Cr18Ni9Ti

|

1Cr18Ni9Ti

|

|

9

|

Adjusting Bolt

|

45

|

2Cr13

|

2Cr13

|

|

10

|

Cap

|

ZG200-400

|

1Cr18Ni9Ti

|

1Cr18Ni9Ti

|

|

|

Sealing surface of seat and disc

|

|

Co Depositing stellite

|

Dimensions (mm):

|

Type

|

(DN)

|

do

|

d

|

M

|

D

|

K

|

Z-d

|

b

|

d1

|

M1

|

D1

|

k1

|

Z1-d1

|

b1

|

L

|

L1

|

H

|

|

A41Y-160(

|

15

|

8

|

20

|

M24*2

|

95

|

60

|

3-18

|

20

|

/

|

M33*2

|

36

|

/

|

/

|

/

|

50

|

80

|

85

|

|

20

|

10

|

25

|

M27*2

|

95

|

60

|

3-18

|

20

|

/

|

M33*2

|

48

|

/

|

/

|

/

|

50

|

80

|

85

|

|

25

|

12

|

28

|

M33*2

|

105

|

68

|

3-18

|

20

|

/

|

M33*2

|

48

|

/

|

/

|

/

|

50

|

80

|

85

|

|

A41Y-160

|

10

|

8

|

18

|

M24*2

|

95

|

60

|

3-18

|

20

|

29

|

M42*2

|

115

|

80

|

4-18

|

22

|

95

|

100

|

261

|

|

15

|

8

|

20

|

M24*2

|

95

|

60

|

3-18

|

20

|

29

|

M42*2

|

115

|

80

|

4-18

|

22

|

95

|

100

|

261

|

|

20

|

10

|

27

|

M33*2

|

105

|

68

|

3-18

|

20

|

29

|

M42*2

|

115

|

80

|

4-18

|

22

|

95

|

100

|

261

|

|

25

|

12

|

28

|

M33*2

|

105

|

68

|

3-18

|

20

|

50

|

M64*3

|

165

|

115

|

6-26

|

32

|

130

|

135

|

285

|

|

32

|

12,14,16

|

37

|

M42*2

|

115

|

80

|

4-18

|

22

|

50

|

M64*3

|

165

|

115

|

6-26

|

32

|

10

|

135

|

285

|

|

40

|

20

|

47

|

M52*2

|

165

|

115

|

6-26

|

28

|

65

|

M80*3

|

200

|

145

|

6-29

|

40

|

165

|

165

|

350

|

|

50

|

25

|

58

|

M64*3

|

165

|

115

|

6-26

|

32

|

80

|

M100*3

|

225

|

170

|

6-33

|

80

|

165

|

165

|

380

|

|

A41Y-320

|

10

|

8

|

18

|

M24*2

|

95

|

60

|

3-18

|

20

|

29

|

M42*2

|

115

|

80

|

4-18

|

22

|

95

|

100

|

261

|

|

15

|

8

|

27

|

M33*2

|

105

|

68

|

3-18

|

20

|

29

|

M42*2

|

115

|

80

|

4-18

|

22

|

95

|

100

|

261

|

|

20

|

10

|

30

|

M36*2

|

110

|

75

|

3-18

|

20

|

29

|

M42*2

|

115

|

80

|

4-18

|

22

|

95

|

100

|

261

|

|

25

|

12

|

35

|

M42*2

|

115

|

80

|

4-18

|

22

|

50

|

M64*3

|

165

|

115

|

6-26

|

32

|

130

|

135

|

285

|

|

32

|

12,14,16

|

41

|

M48*2

|

135

|

95

|

4-22

|

25

|

50

|

M64*3

|

165

|

115

|

6-26

|

32

|

130

|

135

|

285

|

|

40

|

20

|

58

|

M64*3

|

165

|

115

|

6-26

|

32

|

65

|

M80*3

|

200

|

145

|

6-29

|

40

|

165

|

115

|

350

|

|

50

|

25

|

70

|

M80*3

|

200

|

145

|

6-29

|

40

|

80

|

M100*3

|

225

|

170

|

6-33

|

50

|

165

|

|