In a Closed Spring Loaded Low Lift Type Safety Valve, the disc rotates just a quarter of an inch of the bore diameter. Because the disc only moves up a little distance, their capacities of themselves are often quite a bit smaller than those of full or high-lift valves, and the discharge area is wholly determined by the disc’s position. In the event that there is an overpressure condition, a Closed Spring Loaded Low Lift Type Safety Valve will be fitted so that the pressurized system or vessel will not sustain any harm.

Benefits

- In steam systems, GMK Closed Spring Loaded Low Lift Type Safety Valve is often used for the purpose of providing protection against boiler overpressure in addition to serving other purposes, such as being installed downstream of pressure lowering devices.

- Although its principal function is to provide safety, it is also used in the processing industry to protect products from being harmed as a result of excessive pressure.

|

NO.

|

Name of part

|

A41Y-160

A41Y-320 Materials

|

A41Y-160P

A41Y-320P Materials

|

A41Y-160R

A41Y-320R Materials

|

|

1

|

Flange

|

35/35CrMoA

|

2Cr13

|

1Cr18Ni9Ti

|

|

2

|

Nozzle

|

2Cr13

|

1Cr18Ni9Ti

|

1Cr18Ni12Mo2Ti

|

|

3

|

Body

|

35/40

|

1Cr18Ni9Ti

|

1Cr18Ni12Mo2Ti

|

|

4

|

Disc

|

2Cr13

|

1Cr18Ni9Ti

|

1Cr18Ni12Mo2Ti

|

|

5

|

Guide sleeve

|

2Cr13

|

1Cr18Ni9Ti

|

1Cr18Ni12Mo2Ti

|

|

6

|

Spring

|

50CrVA

|

50CrVA Coated Teflon

|

50CrVA Coated Teflon

|

|

7

|

Stem

|

2Cr13

|

1Cr18Ni9Ti

|

1Cr18Ni12Mo2Ti

|

|

8

|

Bonnet

|

ZG230-450

|

1Cr18Ni9Ti

|

1Cr18Ni9Ti

|

|

9

|

Adjusting bolt

|

45

|

2Cr13

|

2Cr13

|

|

10

|

Cap

|

ZG200-400

|

1Cr18Ni9Ti

|

1Cr18Ni9Ti

|

|

|

Sealing surface of seat and disc

|

|

Co Depositing stellite

|

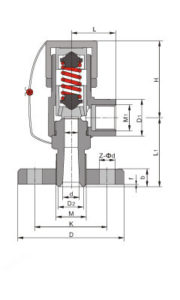

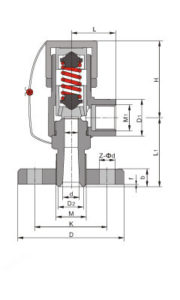

Dimension(mm)

|

Type

|

(DN)

|

do

|

d

|

M

|

D

|

K

|

Z- d

|

b

|

d1

|

M1

|

D1

|

k1

|

Z1- d1

|

b1

|

L

|

L1

|

H

|

|

A41Y-160

(

|

15

|

8

|

20

|

M24 2

|

95

|

60

|

3-18

|

20

|

/

|

M33 2

|

36

|

/

|

/

|

/

|

50

|

80

|

85

|

|

20

|

10

|

25

|

M27 2

|

95

|

60

|

3-18

|

20

|

/

|

M33 2

|

48

|

/

|

/

|

/

|

50

|

80

|

85

|

|

25

|

12

|

28

|

M33 2

|

105

|

68

|

3-18

|

20

|

/

|

M33 2

|

48

|

/

|

/

|

/

|

50

|

80

|

85

|

|

A41Y-160

|

10

|

8

|

18

|

M24 2

|

95

|

60

|

3-18

|

20

|

29

|

M42 2

|

115

|

80

|

4-18

|

22

|

95

|

100

|

261

|

|

15

|

8

|

20

|

M24 2

|

95

|

60

|

3-18

|

20

|

29

|

M42 2

|

115

|

80

|

4-18

|

22

|

95

|

100

|

261

|

|

20

|

10

|

27

|

M33 2

|

105

|

68

|

3-18

|

20

|

29

|

M42 2

|

115

|

80

|

4-18

|

22

|

95

|

100

|

261

|

|

25

|

12

|

28

|

M33 2

|

105

|

68

|

3-18

|

20

|

50

|

M64 3

|

165

|

115

|

6-26

|

32

|

130

|

135

|

285

|

|

32

|

12.14.16

|

37

|

M42 2

|

115

|

80

|

4-18

|

22

|

50

|

M64 3

|

165

|

115

|

6-26

|

32

|

130

|

135

|

285

|

|

40

|

20

|

47

|

M52 2

|

165

|

115

|

6-26

|

28

|

65

|

M80 3

|

200

|

145

|

6-29

|

40

|

165

|

165

|

350

|

|

50

|

25

|

58

|

M64 3

|

165

|

115

|

6-26

|

32

|

80

|

M100 3

|

225

|

170

|

6-33

|

80

|

165

|

165

|

380

|

|

A41Y-320

|

10

|

8

|

18

|

M24 2

|

95

|

60

|

3-18

|

20

|

29

|

M42 2

|

115

|

80

|

4-18

|

22

|

95

|

100

|

261

|

|

15

|

8

|

27

|

M33 2

|

105

|

68

|

3-18

|

20

|

29

|

M42 2

|

115

|

80

|

4-18

|

22

|

95

|

100

|

261

|

|

20

|

10

|

30

|

M36 2

|

110

|

75

|

3-18

|

20

|

29

|

M42 2

|

115

|

80

|

4-18

|

22

|

95

|

100

|

261

|

|

25

|

12

|

35

|

M42 2

|

115

|

80

|

4-18

|

22

|

50

|

M64 3

|

165

|

115

|

6-26

|

32

|

130

|

135

|

285

|

|

32

|

12.14.16

|

41

|

M48 2

|

135

|

95

|

4-22

|

25

|

50

|

M64 3

|

165

|

115

|

6-26

|

32

|

130

|

135

|

285

|

|

40

|

20

|

58

|

M64 3

|

165

|

115

|

6-26

|

32

|

65

|

M80 3

|

200

|

145

|

6-29

|

40

|

165

|

115

|

350

|

|

50

|

25

|

70

|

M80 3

|

200

|

145

|

6-29

|

40

|

80

|

M100 3

|

225

|

170

|

6-33

|

50

|

165

|

165

|

380

|