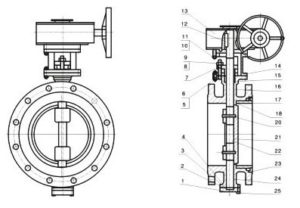

Cryogenic Triple Offset Butterfly Valve

GMK is excited to provide a comprehensive selection of butterfly valves suitable for a broad variety of services, ranging from cryogenic to applications involving high temperatures. GMK cryogenic triple-offset butterfly valve helps to regulate the flow of liquid nitrogen, which is used in the process of liquefying natural gas. The current barrier is a double-layer construction that is built of latex and steel sealing respectively. Due to the limited endurance of the rubber seal, it must be changed regularly. Additionally, the flexibility of the metal seal diminishes in the cryogenic condition, which results in nitrogen escaping through the seal.

- Size:2″-60″

- Pressure:150LB,300LB,600LB,900LB

- Material:LCB, LCC, CF8, CF8M, CF3, CF3M ect

- Connection:Wafer type,Lug type,Flange,BW

- Operate:Handwheel, Gearbox, Penumatic Actuator