Looking for a reliable filtration system that can effectively remove debris and unwanted particles from your fluid or gas flow? Look no further than the Y type strainer! These versatile devices are specially designed to provide effective filtration in a wide range of applications, making them an essential component in many industrial processes. But with so many different types of Y strainers available on the market, how do you choose the right one for your needs? In this blog post, we’ll explore everything you need to know about selecting the perfect Y type strainer for your specific application. So let’s dive in and discover what sets these powerful little devices apart!

What is a Y Type Strainer?

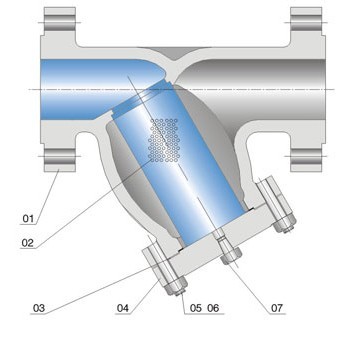

A Y type strainer is a type of mechanical filter that is used to remove unwanted particles from fluid or gas flows. As its name suggests, this device has a distinctive ‘Y’ shape, with an inlet and outlet on opposite sides of the unit.

The main function of a Y type strainer is to trap debris and other contaminants in order to prevent them from entering downstream equipment. This can help to protect pumps, valves, meters, and other critical components from damage caused by foreign objects.

One of the key advantages of using a Y type strainer is that it offers excellent filtration capabilities without significantly impeding flow rates. This makes these devices ideal for use in high-pressure systems where maintaining consistent flow rates is essential.

Another benefit of using a Y type strainer is that they are generally easy to install and maintain. Most models can be installed directly into existing pipelines without any modification required, while routine maintenance tasks typically involve little more than removing the basket for cleaning or replacement as needed.

If you’re looking for an effective way to ensure your fluid or gas system stays free from harmful contaminants and blockages, then investing in a quality Y-type strainer could be just what you need!

Different Types of Y Type Strainers

Y type strainers are available in various types, each designed to handle specific applications. One of the most common types is a perforated basket Y strainer. This type of strainer features a wire mesh that’s made from stainless steel or other materials and has small holes for filtering out impurities.

Another type is the fabricated Y strainer which is usually custom-designed to meet unique application requirements. They offer more flexibility compared to their cast counterparts, as they can be configured with different inlet/outlet sizes and shapes.

Self-cleaning Y strainers are also popular in industries such as oil and gas where there may be high solids loading, requiring frequent cleaning. These self-cleaning types feature an automatic backwash mechanism that filters out debris buildup without interruption of flow.

Magnetic Y-type strainers come equipped with strong magnets that attract ferrous particles suspended in fluids passing through them while allowing clean fluids to pass freely.

It’s essential to understand your application needs before selecting a particular type of Y-strainer. Each has its own distinct advantages and limitations, so it’s critical always to consult with experts who can help make an informed decision based on your specific filtration needs.

Materials

When it comes to choosing the right Y type strainer for your application, one of the key factors to consider is the material. There are a variety of materials available, each with its own advantages and disadvantages.

Firstly, let’s talk about stainless steel. This material is durable and corrosion-resistant, making it a great choice for applications where there may be exposure to harsh chemicals or high temperatures. However, stainless steel can be more expensive than other materials.

Another popular option is bronze. It has excellent resistance against saltwater as well as being non-sparking in nature which makes it safe in certain industries such as oil exploration and production platforms. However, Bronze filters are usually bigger than their counterparts made from different metals because they tend to have lower working pressures compared to others.

Plastic Y strainers are suitable for use with corrosive fluids but only when used at low pressure ranges since most plastics typically have inferior mechanical properties that cannot withstand high pressure levels.

Ultimately, selecting the appropriate Y type strainer material will depend on various factors like fluid characteristics (corrosiveness), temperature range requirements, pressure ratings etc., so you’ll want to consult with an expert before choosing what’s best for your particular application.

How to Size a Y Type Strainer

When it comes to selecting the right Y type strainer for your application, size is an important factor to consider. The sizing process involves determining the appropriate diameter of the strainer based on factors such as flow rate and pipe size.

Firstly, consider your system’s flow rate, which is typically measured in gallons per minute (GPM). This information helps determine the required open area of the strainer basket. A larger flow rate requires a larger basket with more open area to prevent clogging and pressure drop.

Next, take into account your pipeline’s diameter or nominal pipe size (NPS). It’s crucial to select a strainer with an NPS that matches or exceeds that of your piping system. Choosing a smaller strainer can cause blockages and higher pressure drops in the line.

It’s also essential to consider any debris or contaminants present in your fluid stream. If it contains large particles or high levels of solids, you may need a bigger basket than what would be recommended based on just flow rate and pipeline diameter alone.

Proper sizing ensures that your Y type strainer functions effectively without causing undue resistance or damage within your system.

Advantages and Disadvantages of Y Type Strainers

Y type strainers are a popular choice for industrial applications due to their effectiveness in removing debris and contaminants from liquid or gas flow. However, like any other equipment, Y type strainers come with both advantages and disadvantages.

One of the main advantages of using Y type strainers is their ability to filter out unwanted particles efficiently. These can include dirt, sand, rust, and other foreign objects that can cause damage to downstream equipment. By preventing these impurities from entering the system, it helps improve overall product quality and reduces downtime caused by maintenance issues.

Another advantage is that Y type strainers are simpler in design than some other types of filters or separators – making them easier to install and maintain. They also tend to have a longer life span compared to some other filter types.

However, there are also several disadvantages associated with Y type strainer usage. One such disadvantage is that they can be more prone to clogging than some other filters – especially if they aren’t regularly cleaned or replaced when needed.

Additionally, while they do offer effective filtration capabilities for smaller particle sizes (down to around 50 microns), larger particles may require a different filtration method altogether since not all materials used in constructing Y-type screens are strong enough for this purpose.

Though when properly sized and maintained according to the application requirements – y-type straining systems offer an efficient means of protecting critical components against contamination ensuring long service life at reduced costs over time!

Conclusion

Choosing the right Y type strainer for your application is crucial to ensure its effectiveness and efficiency. With the different types of Y type strainers available in the market, it can be challenging to make a decision on which one to use. It is essential to consider factors such as materials, sizing, and advantages and disadvantages when choosing a Y type strainer.

When selecting a material for your Y type strainer, it’s important to choose one that is compatible with the fluid being filtered. Stainless steel or brass are popular choices due to their corrosion resistance properties.

Sizing also plays an integral role in choosing a Y type strainer as it determines how much flow rate will pass through. Proper sizing ensures that there will be no clogging issues during operation.

The advantages of using a Y-type strainer include efficient filtration with minimal pressure drop and ease of maintenance. However, some disadvantages include high initial costs compared to other filters and limitations on filtering small particles.

Understanding the different types of Y type strainers available, considering factors like material compatibility and proper sizing along with weighing their advantages and disadvantages are key steps when deciding on which one best suits your needs. By following these guidelines closely you’ll be able to select with confidence from among all options out there!