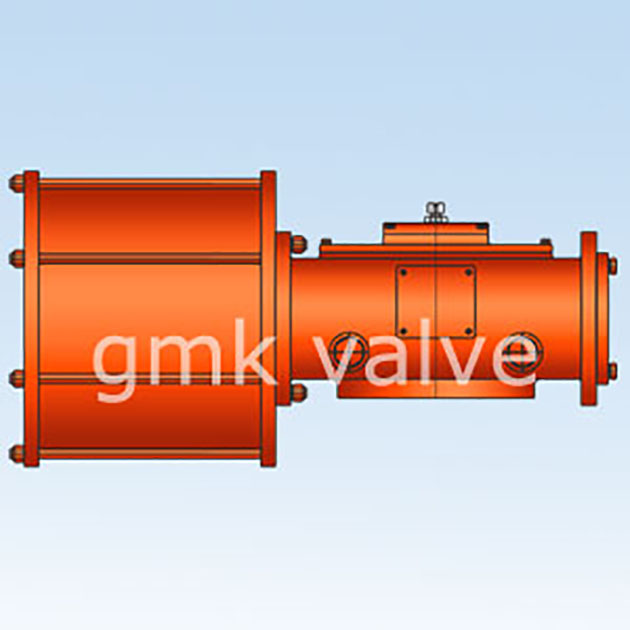

Double-acting Pneumatic Actuator

GMK double-acting pneumatic actuator has a piston that is operated upon by air or liquid from both sides of the device. To open the valve, a larger pressure is given to one side. The opening and closing of the valve are determined by the flow of either air or liquid. GMK double-acting pneumatic actuator performs very well if significant torque loads are needed in either the forward or backward modes of motion. This actuator is also the standard in businesses that demand a powerful push, such as the oil and gas industries. It is used extensively in these fields.