In double-acting & manual type actuators, the opening and shutting of valves are performed by the use of air pressure. It is the design that constitutes the vast majority of pneumatic valve actuators. Because most versions do not have mechanical springs, double-acting actuators are the best option to go with because of their low cost and great endurance. It makes them the favored choice. Double-acting actuators of sufficient quality may often complete millions of cycles before failing.

Benefits

- Double-acting actuators are the best solution if the valve fails to the closed (or open) position when power is disconnected, and/or if the cycle rate is high.

- There is widespread usage of double-acting actuators may be attributed to the low cost of these devices as well as their high level of endurance.

- Actuators having a double-acting mechanism could be the sole suitable option for use in applications with restricted space.

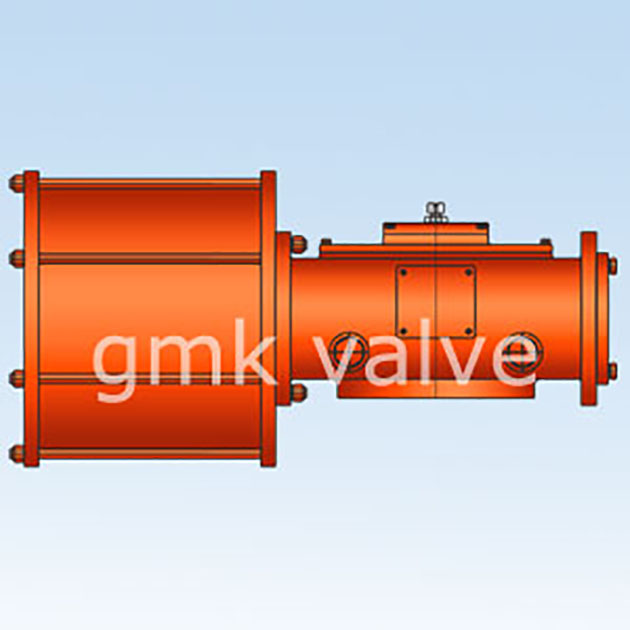

- GMK Double acting actuator has the longevity of a double-acting actuator in order to achieve the desired effect.

- The double-acting design of the actuator kicks in when the power or air pressure is turned off, and due to the springs, the valve goes back to its normal position once it has been moved.