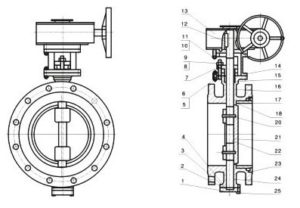

Triple Offset Butterfly Valve

The Triple Offset Butterfly Valves offered by GMK are put to use in a wide variety of sectors across the world, particularly those that deal with liquids and gases. The triple offset valves can withstand temperatures of up to 815 degrees Celsius and are suitable for use in cryogenic applications. Even under conditions of significant temperature change and pressure peaks, the triple offset design and the specific characteristics ensure that there will be minimal leakage at all times. One kind of butterfly valve known as a triple-offset butterfly valve has three offsets in total. The placement of the shaft in relation to the center line of the bore and the center line of the disc/seat sealing surfaces are both taken into consideration by two of these.

- Size:2″-80″

- Pressure:150LB,300LB,600LB,900LB

- Material:Cast iron,Ductile iron,WCB,LCB,LCC,WC5,WC6,WC9,CF8,CF8M,CF3,CF3M,B148 etc.

- Connection:Wafer type,Lug Type,Flange,BW

- Operation:Handwheel,Gearbox,Pneumatic Actuator