◆Apply to every kinds of petroleum、chemical、medical、energy resources、special fluid or gas etc medium.

◆Explosion-proof class:BS5501:IIA、IIB、IIC.

◆Body material:carbon steel、aluminum alloy、stainless steel:SUS304、SUS304L、SUS316、SUS316L.

◆Disc、seat material:aluminum alloy、stainless steel.

◆Sealing material:PTFE.

◆Connection type:flange and thread.

◆Flange standard:HG20592 If customer need standard GB、SH、HGJ、JB、ANSI、JIS etc or change pressure class,please remark on the order contract.

◆Manufacture 、inspection standard:according to (petroleum storage tank breathing valve) SY/T0511.1-2010、(petroleum storage tank flame retar- dant performance and test method). GB5908-86 standard implement manufature and inspection or customer required standard.

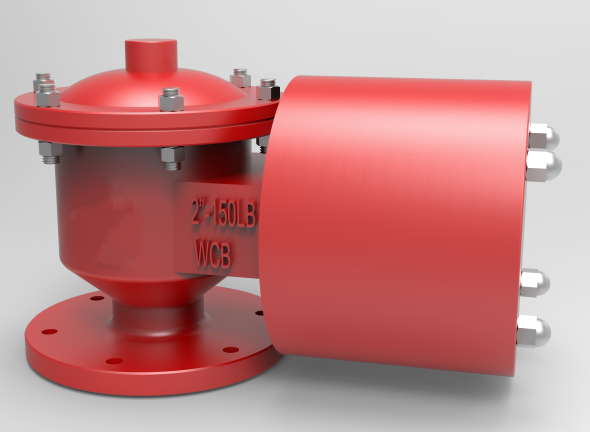

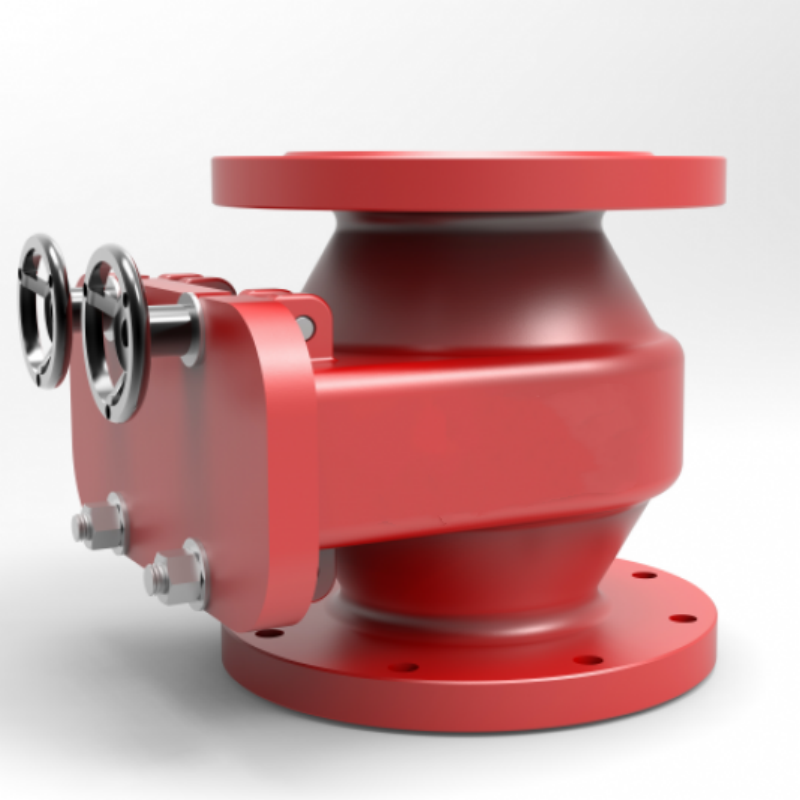

Breather Valve With Flame Arrester

ZCPE-pilot operated breather valve with flame arrester is a bit different with breather valve ,first let the seat leakage closer to set point ,second full flow without overpresure ,to maintain the tank pressure balance, reduce safety energy-saving products medium volatile, but also the use of principles of vapor heat transfer, protect the respiratory valve parts is not easy to freeze, the breathing valve to ensure the normal work, equipped with fire retardant explosion-proof function.

Fire breathing valve produced by our company has simplified structure, ventilation volume, less leakage, corrosion resistance, insulationetc.. The valve adopts polytetrafluoroethylene material, has the advantages of low temperature resistant, anti frost. The electrostaticprotection device is provided with a respiratory valve, the valve and the tank to keep the same potential moment.

Under normal circumstances, (fire) breathing valve operating pressure to B shall prevail;

Applicable materials: gasoline, kerosene, diesel, aromatics, sulfur, air and other petrochemical materials;

Environment temperature: -40 °C -+60 °C;

Shell material: HT, AL, A3, 18-8, 304, 304L, 316, 316L.

Flange standards: HG20592-97 PN1.0 (also can be produced according to user specified criteria)