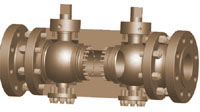

Double Block And Bleed Ball Valve

GMK double block and bleed valves offer the highest level of protection possible in double isolation and bleed service. These valves combine two in-line isolation valves into a single body and include an additional bleed valve that is used to empty or vent fluid that is trapped in between the two obturators. This design allows for the maximum degree of safety possible in double isolation and bleeds service. When transferring liquids and gases, using one valve that combines the functions of a block and bleeds rather than two separate valves results in more space-efficient piping and much-reduced air loss. There is a wide range of one-of-a-kind alternatives available, each of which offers cutting-edge technology solutions. It is possible to tailor the material choices to the specific requirements of unique projects.

- Size:1/2″-24″

- Rating:150LB,300LB,600LB,900LB,1500LB

- Material:A105,WCB, LCB,LCC, WC6,WC9, C5,C12,C12A, CF8, CF8M, CF3, CF3M, CK20, CN7M, CD4MCu, CK3MCuN, Cu5MCuC, CN3MN, M35-1,B148 ect

- Connection:RF Flanges,RTJ Flange,Butt Weld,Hub end,Groove

- Operation:Hand lever, Gearbox, Penumatic Actuator