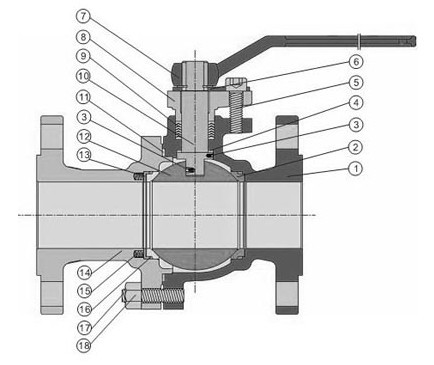

GMK Metal To Metal Seat Ball Valve

After realizing the limitations of their soft-seat equivalents, manufacturers developed metal-seated ball valves. Oil refineries, petrochemical plants, mining operations, pulp and paper mills, iron and steel mills, electric power generation, and water treatment plants can all benefit from their use because of their resistance to high temperatures, cryogenic conditions, abrasive mediums, slurries, and the need for flow control. Ball valves are a type of quarter-turn, the low-torque valve that offers low flow resistance and is used in on/off utility and process applications. Even though they have outstanding control characteristics and a straight-through design, they are rarely employed for throttling. Many ball valves use polytetrafluoroethylene (PTFE) or nitrile butadiene rubber for their soft-seat inserts since these materials are thermoplastic and highly resistant to wear (NBR). 316 stainless steel or Monel are common examples of metals used for the seat in metal-seated ball valves. You should only use thermoplastic sealing in sterile environments. They shouldn’t be subjected to harsh conditions like hot or severely low temperatures, or to any kind of grit or grime. Metal-seated ball valves are frequently used in harsh service environments.

- Size:2″-24″

- Rating:150LB, 300LB, 600LB, 900LB, 1500LB

- Material:WCB, LCB, LCC, WC6, WC9, C5, C12, C12A, CF8, CF8M, CF3, CF3M, CN7M, Alloy 20, B148, UB6, Hastelloy C etc

- Connection:Flanges, RTJ flange, butt weld, hub end, groove

- Operate :Hand level, gearbox, pneumatic actuator