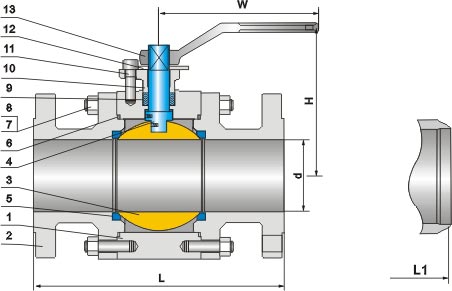

GMK Forged Steel Floating Ball Valve

Imagine a ball being held in place between two seats in order to understand the inner workings of a forged steel floating ball valve. Under the medium pressure action, the ball is able to generate a displacement that is sufficient enough to press on the seat seal ring at the outlet, so ensuring that the seal will not leak. It has an anti-fire design according to the Fire Protection Standards. It is a device used for dissipating static electricity. Between the stem and the ball, as well as between the stem and the body, there is a static-conduction spring that has been inserted. The discharge of static energy to the ground eliminates any risks that might have been posed to the system. It offers torque reduction in operational settings. The fourth factor is the uncontrolled loss of body fluids. Construction that is waterproof and airtight. The double gasket and O-ring seal that is located between the valve body and the bonnet is impenetrable by fire, high temperatures, stress, or an uneven opening or closing of the torque. These factors have no chance of breaking the seal.

- Size:1/2″-12″

- Pressure:150LB, 300LB, 600LB, 900LB, 1500LB

- Material:WCB, LCB, LCC, WC6, WC9, C5, C12, C12A, CF8, CF8M, CF3, CF3M, CN7M, Alloy 20, B148, UB6 904l, Hastelloy C etc

- Connection:Flanges, RTJ flange, butt weld, hub end, groove

- Operate:Lever, wormgear, gearbox, penumatic actuator