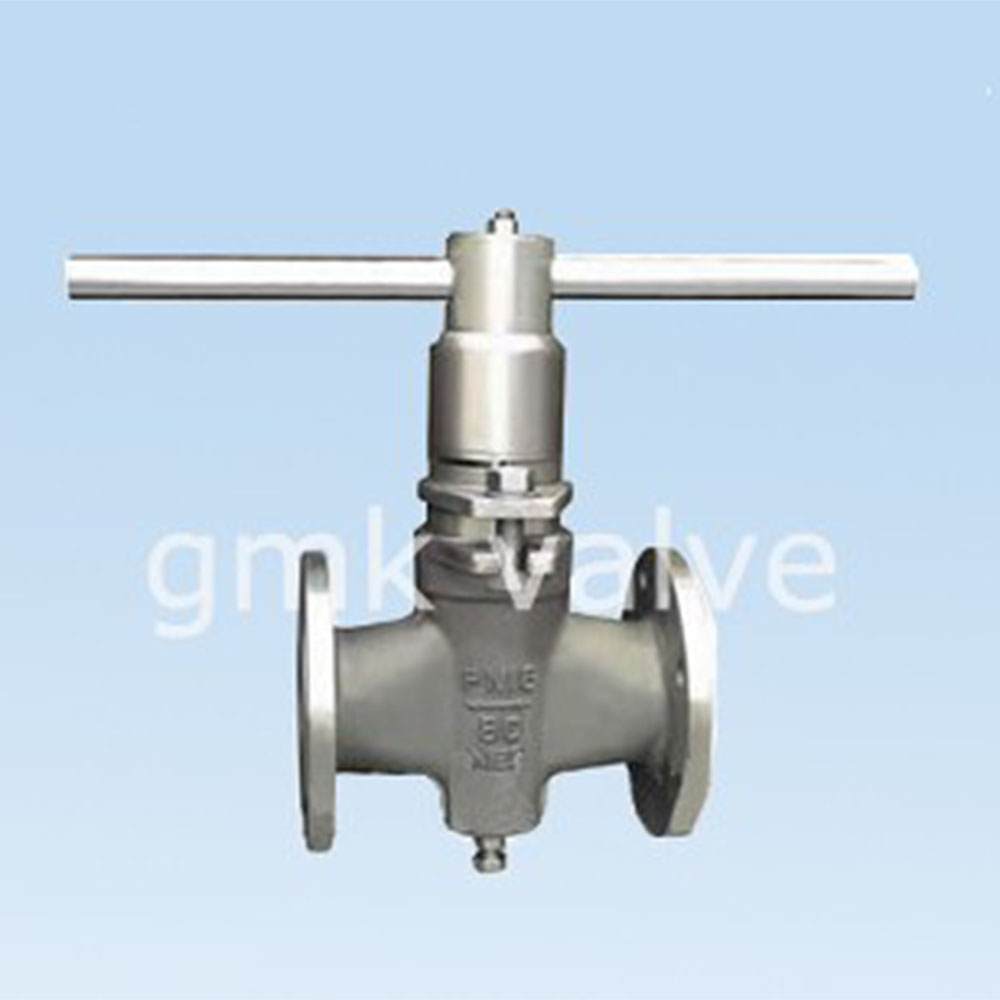

Zirconium Regulating Valve

GMK Zirconium regulating valve is an exotic material that has unique physicochemical protection against corrosion. Because of this, it has been extensively used in special rigorous processes, and it flaunts implementations that cannot be replaced in the nuclear industry, the aircraft industry, the aviation industry, and the chemical industry. GMK zirconium regulating valves have a good ability to withstand high-temperature chemicals, which makes them very desirable. Industries using acetic acid or heat transfer pipelines operating at high temperatures are common places to see them employed. In addition to this, you can use GMK regulating valves in nuclear power plants.

- Size:DN15-400mm,NPS1/2″-16″

- Body Material:Zirconium702,Zirconium705

- Pressure:PN1.0-PN6.4