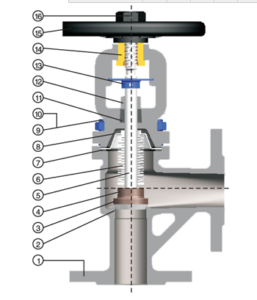

Angle Bellows Seal Globe Valve

The body design of an Angle Bellows Seal Globe Valve uses a pattern globe valve, and bellow seal element as its foundation. The sealing surface of the angle globe valve can be flat or conical, and the flap travels in a straight line along the centerline of the fluid as it opens and closes. It has a flow coefficient that is much lower. It is able to withstand the slugging effect of this sort of flow, which makes them helpful in circumstances in which the flow is cyclical and pulsating. This makes GMK Angle Bellows Seal Globe Valve valuable.

- Supply Ability:10000 Piece/Pieces per Month

- Port:Wenzhou/shanghai

- Payment Terms:L/C,D/A,D/P,T/T