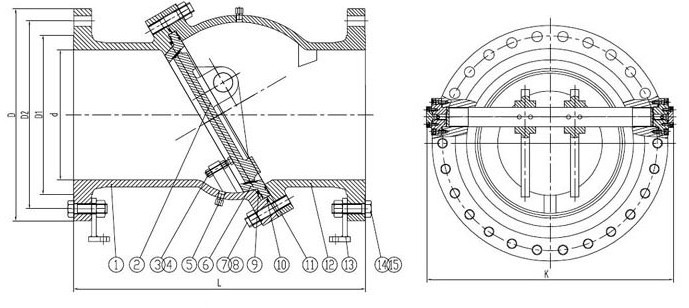

GMK Tilting Disc Check Valve

The term “tilting disc check valve” refers to a specific type of check valve. In a plumbing system, check valves are used to stop the flow in the opposite direction. In a pipeline system, the flow of the material operates these valves. The valve opens when the fluid pressure in the system is high enough, and it closes when the flow direction changes. The check mechanism’s own weight, back pressure, a spring, or a combination of these forces bring the lid down. Swing, tilting disk, piston, butterfly, and stop are the common varieties of check valves. The swing check valve and the tilting disc check valve are quite similar in design. The straight-through design of the tilting disc type, like that of the swing check, reduces fluid resistance and turbulence. In both horizontal and vertical lines with the upward flow, tilting disc check valves can be installed. In bigger diameter valves, some designs can be installed by merely fitting between two flange faces, making for a lightweight, space-saving setup.

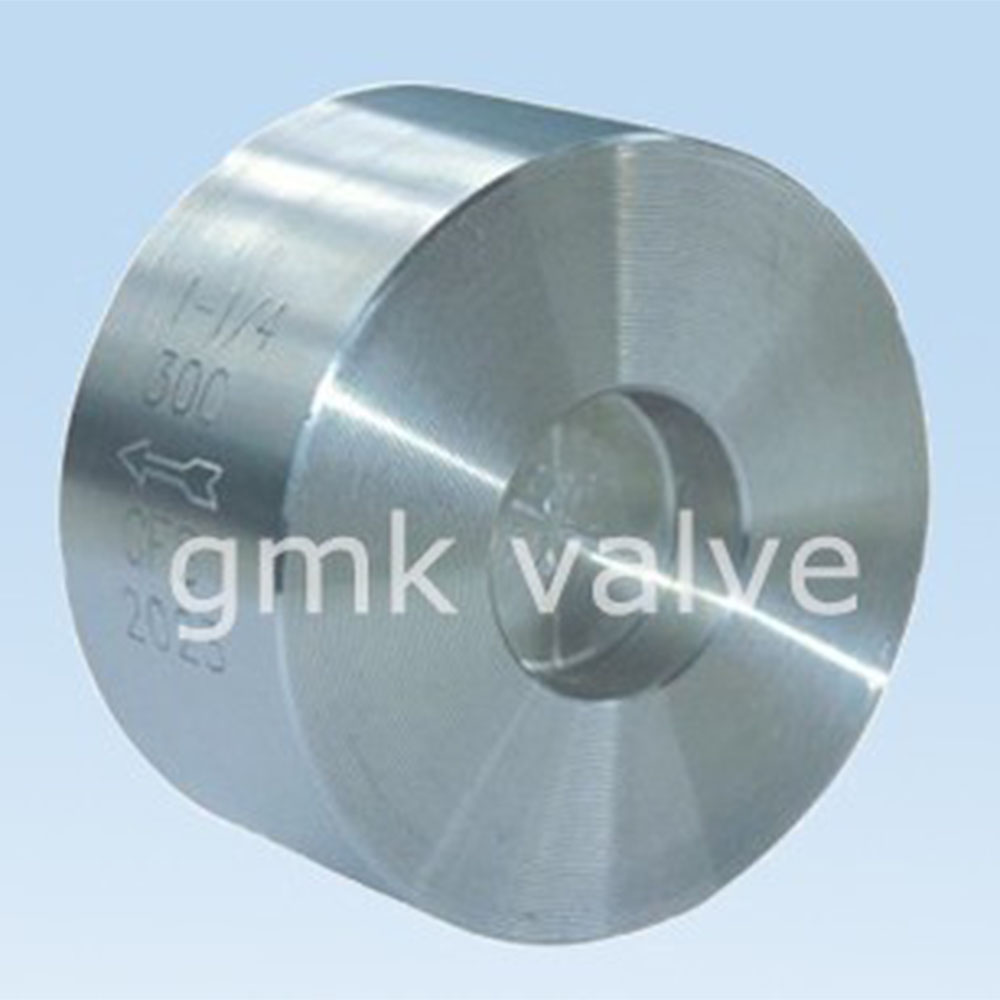

- Size:2″-36″

- Rating:150LB, 300LB, 600LB, 900LB, 1500LB

- Material:WCB, LCB, LCC, WC6, WC9, C5, C12, C12A, CF8, CF8M, CF3, CF3M, CN7M, Alloy 20, B148, UB6, Hastelloy C etc

- Connection:Flanges, RTJ flange, butt weld