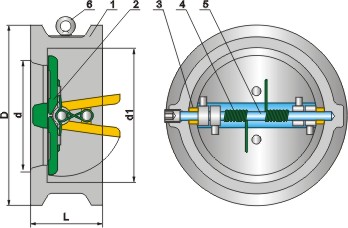

GMK Wafer Check Valve

A wafer check valve’s movable disc opens and closes to regulate flow. The compact shape of these valves makes them ideal for use in places where a flanged check valve would be impractical. Wafer check valves have formed bodies around the disc’s orifice. The addition of a valve body, as opposed to the skeleton wafer check, significantly improves the valve’s operation. A flanged check valve’s disc has a small opening in the pipe since the valve is flanged into place. This means the check valve itself may impede flow. However, wafer check valves’ molded bodies allow the disc to swing open all the way, allowing for maximum flow. For obvious reasons, this is crucial if your program needs uninterrupted data transfer. Because of this, we often stock swing check valves for use when a full port valve is needed and wafer check valves for use when the flow is not a concern. A wafer check valve’s movable disc can either allow flow through or close off the valve. They can be installed in places where a flanged check valve would not fit, thanks to their compact shape. Valves made from wafers use molded bodies around the disc’s opening.

- Size:2″-48″

- Pressure:150LB, 300LB, 600LB, 900LB, 1500LB, 2500LB

- Material:WCB, LCB, LCC, WC6, WC9, C5, C12, C12A, CF8, CF8M, CF3, CF3M, CN7M, Alloy 20, B148, UB6, Hastelloy C etc

- Connection:Wafer, lug-wafer, flanges, RTJ flange