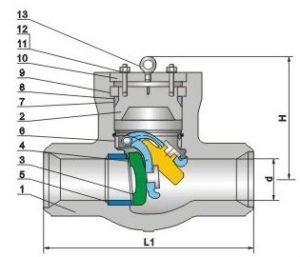

Pressure Seal Check Valve

GMK Pressure Seal Check Valve is a selection of valves that have been developed in accordance with ASME standard B16.34. It Can be purchased in Swing Check, Piston Check, and Tilting Disc varieties (Y and T pattern design). It was developed to always provide the highest possible level of flow efficiency and safety. The dimensions are from end to end by ASME B16.10. Swing check valves and tilting disc check valves are both suitable for installation on horizontal as well as vertical (upflow) pipes. Stop check valves, also known as Y and T designs, were developed specifically for use on horizontal pipework.

- Size:2″-30″

- Pressure:900LB,1500LB,2500LB

- Material:WCB, LCB,LCC, WC6,WC9, C5,C12,C12A, CF8, CF8M, CF3, CF3M, CN7M,Alloy 20,B148,UB6 ,Hastelloy C etc

- Connection:Flanges,RTJ Flange,Butt Weld,Hub end,Groove